Offers & project inquiries for powder coating systems

Request a customized quote for powder coating booths, ovens, conveyor technology, powder application systems, pretreatment facilities, or spare parts. We deliver technical concepts, binding cost estimates, and detailed data sheets—quickly, transparently, and tailored to your project.

Our service portfolio (What you can request)

- Complete systems (turnkey solutions): Planning, delivery, assembly, and commissioning of coating lines.

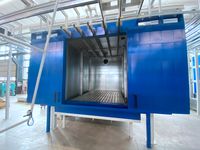

- Individual components: Powder coating booths, ovens, powder centers, powder applicators (Wagner, Gema, Nordson, etc.).

- Conveyor technology & peripherals: Overhead conveyors, indexing/continuous systems, power & free systems, circular/cross conveying.

- Water treatment & wastewater skids: RO, VE polishing, coalescer, batch reactor.

- Spare parts & maintenance packages: Wear parts, service contracts, fast delivery.

- Retrofit & modernization: Control system upgrades, efficiency upgrades, energy-saving measures.

- Engineering & planning: Layout planning (DXF/IFC), P&ID, cycle time/capacity calculations, and profitability analysis/risk analysis.

How our quotation process works (transparent & practice-oriented)

- Submit an inquiry – via form, email, or phone: brief project description, contact person, and desired delivery timeframe.

- Preliminary clarification & documentation – We will request the necessary information (P&ID, hall dimensions, quantities, specifications).

- Technical clarification – A brief phone call, email, or online meeting with our system planner to finalize the specifications.

- Cost calculation & quotation – You will receive a technical quotation including price, delivery time, scope definition, and any optional variants.

- Workshop planning & approval – After order placement, we will create workshop drawings, interface DXF files, and an assembly plan.

- Delivery & commissioning – Assembly, testing, acceptance testing, and documented handover, including training.

- After-sales service – Spare parts supply, maintenance contracts, and remote support.

Tip: For faster quotes, please upload datasheets, photos or P&ID via email in the first step — this saves time.

What we need for a concrete, binding offer

- Brief description of the project/product (e.g., "Powder cabinet, 3,000 × 2,000 mm, floor extraction")

- Quantity/throughput (pieces/shift)

- Maximum workpiece dimensions and weight

- Hall dimensions and connection data (height, door openings, power, compressed air)

- Interfaces/conveyor concept (DXF or sketch)

- Existing control system/PLC standards (if retrofit)

- Desired delivery date and budget (if applicable)

- Contact details and contact person for inquiries

Types of offers & delivery conditions

- Quick estimate (non-binding): Short-term price indication (usually within 3–5 business days) based on the information provided.

- Technical offer (binding): Detailed cost estimate including scope definition, delivery time, and payment terms (after technical clarification).

- Turnkey project offer: Includes engineering, assembly, and service packages, deadlines, and acceptance conditions.

- Service contracts: (e.g., spare parts terms)